How To Determine Correct Weather Stripping On Commercial Garage Door?

In the world of commercial enterprises, attention to detail is crucial. Every aspect, from infrastructure to operations, impacts success. Yet, amidst the daily bustle, some elements, like garage door weather stripping, often go unnoticed despite their significant role. Weather stripping acts as a shield, protecting commercial spaces from extreme weather and maintaining a comfortable environment. Choosing the right weather stripping demands careful consideration of factors like climate and door type. This article explores the importance of weather stripping and offers guidance on selecting the correct type, empowering businesses to enhance efficiency and success.

Weather Stripping Explained

Weather stripping is a crucial component of any building's insulation system, including commercial garage doors. Essentially, it refers to the sealing materials installed around doors and windows to prevent the infiltration of air, water, dust, and noise from the external environment into the interior spaces. The primary purpose of weather stripping is to create a tight seal between the door and its frame, thereby enhancing energy efficiency, maintaining indoor comfort, and protecting the interior from external elements.

In the context of commercial garage doors, weather stripping plays a vital role in ensuring the functionality and longevity of the door system. By sealing gaps and cracks, weather stripping helps to regulate temperature levels inside the garage, prevent moisture intrusion, and minimize the ingress of debris and pests. Additionally, it reduces noise transmission, creating a quieter and more comfortable working environment for employees.

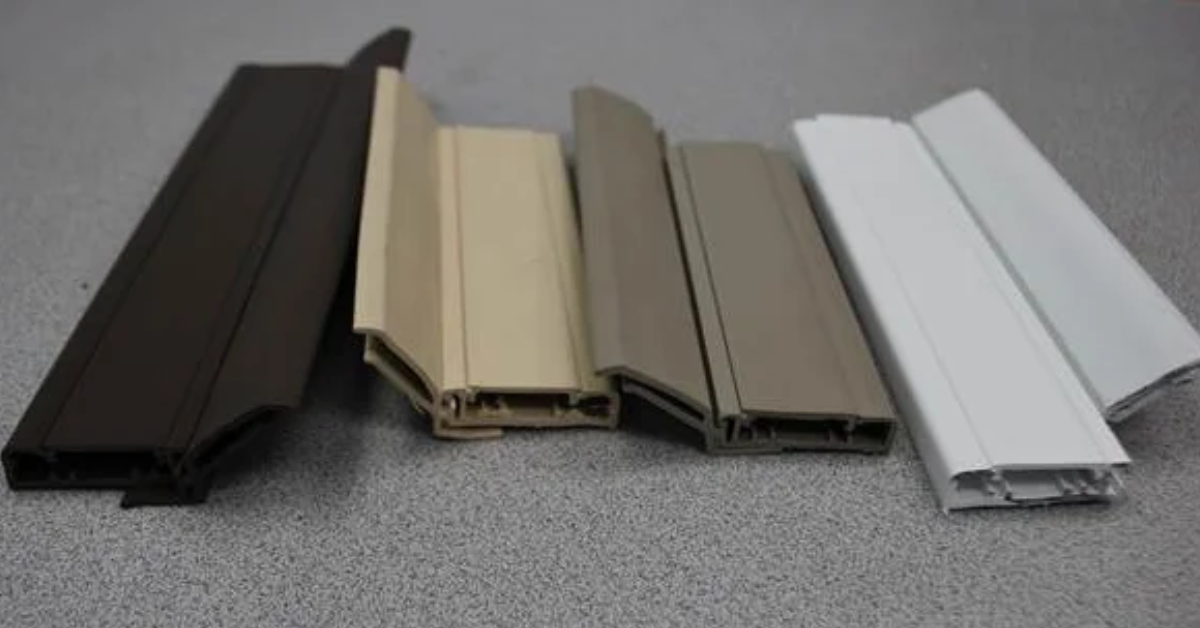

Types of Weather Stripping Materials

There are various types of weather stripping materials available, each offering distinct advantages and suitable for different applications. Common materials include:

Vinyl: Vinyl weather stripping is affordable, easy to install, and resistant to moisture and UV rays. It is suitable for moderate weather conditions and provides adequate sealing for commercial garage doors.

Rubber:

Rubber weather stripping is flexible and durable, making it ideal for sealing irregular surfaces and accommodating movements in the garage door mechanism. It offers good insulation properties and can withstand extreme temperatures.

Foam Tape: Foam tape weather stripping consists of adhesive-backed foam strips that conform to irregular surfaces and fill gaps effectively. It is easy to install and provides excellent insulation against drafts and noise.

Metal:

Metal weather stripping, such as aluminum or stainless steel, offers durability and longevity. It is commonly used in high-traffic areas or where additional security is required. Metal weather stripping can be installed as interlocking strips or as thresholds along the bottom of the garage door.

Felt:

Felt weather stripping is made of compressed fibers and is often used for its affordability and ease of installation. While not as durable as other materials, felt weather stripping provides decent insulation and is suitable for temporary or low-traffic applications.

Choosing the right weather stripping material for a commercial garage door depends on various factors, including the climate, frequency of use, budget, and specific requirements of the door system. Conducting a thorough assessment of the garage door and its surrounding environment is essential to determine the most suitable weather stripping solution.

Assessing Your Commercial Garage Door

Before selecting new weather stripping for your commercial garage door, it's essential to inspect the current weather stripping, if any, to assess its condition and effectiveness. Start by visually examining the perimeter of the door, paying close attention to the areas where the weather stripping is installed. Look for signs of wear and tear, such as cracks, gaps, tears, or detachment from the door or frame.

Run your hand along the weather stripping to feel for any inconsistencies or areas of deterioration. Check for compression and resilience, as weather stripping that has become flattened or rigid may no longer provide a proper seal. Take note of any areas where air, water, or light penetrates through gaps in the weather stripping, as these indicate potential issues that need to be addressed.

Identifying Common Weather Stripping Issues

During the inspection process, you may encounter several common issues with weather stripping on commercial garage doors. These include:

Wear and Tear:

Over time, weather stripping can degrade due to exposure to the elements, frequent use, or physical damage. Signs of wear and tear, such as cracks, splits, or fraying, indicate that the weather stripping may need to be replaced to maintain optimal performance.

Poor Installation: Improper installation of weather stripping can result in gaps or gaps that compromise its effectiveness. Check for inconsistencies in the installation, such as uneven gaps between the weather stripping and the door or frame, and ensure that the weather stripping is securely attached without any loose or missing sections.

Compression Loss:

Weather stripping relies on compression to create a tight seal between the door and its frame. If the weather stripping has lost its resilience and become flattened or compressed, it may no longer provide adequate sealing, allowing air, water, or pests to infiltrate the garage.

Inadequate Coverage: Insufficient coverage of weather stripping can leave gaps or gaps along the perimeter of the door, allowing for the ingress of external elements. Ensure that the weather stripping extends along the entire length of the door and fills any gaps between the door panels or between the door and the frame.

In order to maintain a properly sealed and insulated commercial garage door, you can identify these common weather stripping issues during the assessment process. Whether it involves repairing damaged weather stripping, replacing worn-out materials, or upgrading to more durable solutions, proactive maintenance is essential to preserving the integrity and functionality of the door system.

Factors to Consider

Climate and Environmental Conditions

- The climate and environmental conditions in which your commercial garage door operates play a significant role in determining the appropriate weather stripping. For instance, in regions with extreme temperatures or high humidity levels, you'll need weather stripping materials that offer superior insulation and resistance to moisture. Similarly, areas prone to strong winds or heavy rainfall may require weather stripping that provides excellent weatherproofing and can withstand harsh weather conditions. Consider the specific climate and environmental factors relevant to your location when selecting weather stripping for your garage door to ensure optimal performance and durability.

Frequency of Garage Door Use

- The frequency of use of your commercial garage door is another crucial factor to consider when choosing weather stripping. Garage doors that are opened and closed frequently are subject to more wear and tear, requiring weather stripping materials that can withstand constant movement and compression. Additionally, frequent use may accelerate the deterioration of weather stripping over time, necessitating more frequent inspections and maintenance. Conversely, garage doors that are used infrequently may benefit from weather stripping materials that offer long-lasting durability and resilience against occasional usage.

Material and Durability Requirements

- Selecting the right material and thickness of weather stripping is essential to meet the specific durability requirements of your commercial garage door. Different materials offer varying levels of durability, flexibility, and resistance to environmental factors. For example, rubber weather stripping is known for its durability and flexibility, making it suitable for garage doors that experience frequent movement. On the other hand, vinyl weather stripping is resistant to moisture and UV rays, making it ideal for outdoor applications. Consider factors such as the expected lifespan of the weather stripping, the level of protection required, and any special considerations, such as fire resistance or chemical compatibility, when choosing the material and thickness of weather stripping for your garage door.

Choosing the Right Weather Stripping

The type of garage door you have will influence the selection of weather stripping. Commercial garage doors come in various designs, including sectional doors, rolling doors, and overhead doors, each requiring specific weather stripping solutions. For example, sectional garage doors may require flexible weather stripping that can accommodate the movement of individual panels, while rolling doors may benefit from weather stripping that can withstand repeated rolling and unrolling. Consider the design, operation, and construction of your garage door when selecting weather stripping to ensure a proper fit and effective sealing.

When choosing weather stripping for your commercial garage door, it's essential to select the appropriate material and thickness to meet your specific needs. As mentioned earlier, different materials offer varying levels of durability, flexibility, and weather resistance. Additionally, the thickness of the weather stripping can affect its sealing effectiveness and longevity. Thicker weather stripping may provide better insulation and sealing but may also be more prone to wear and tear over time. Consider factors such as the climate, frequency of use, and material compatibility when selecting the material and thickness of weather stripping for your garage door to achieve optimal performance and longevity.

Installation Process

Before installing weather stripping on your commercial garage door, it's essential to properly prepare the surface to ensure optimal adhesion and sealing. Start by thoroughly cleaning the areas where the weather stripping will be applied, removing any dirt, debris, or old adhesive residue. Use a mild detergent or solvent-based cleaner to remove stubborn stains or grease buildup, and allow the surface to dry completely before proceeding.

Next, inspect the garage door for any damage or defects that may affect the installation of weather stripping. Repair or replace any damaged panels, hinges, or hardware to ensure a smooth and even surface for the weather stripping to adhere to. Also, ensure that the door is properly aligned and functioning correctly to prevent any issues with the operation or sealing of the weather stripping.

Applying Weather Stripping Correctly

Once the garage door is clean and prepared, it's time to apply the weather stripping. Begin by measuring the dimensions of the areas where the weather stripping will be installed, taking into account any gaps or irregularities in the door frame. Cut the weather stripping to the appropriate length using sharp scissors or a utility knife, ensuring a precise fit for each section.

Before applying the weather stripping, carefully read and follow the manufacturer's instructions to ensure proper installation. In most cases, weather stripping will come with adhesive backing for easy application. Peel off the protective backing and press the weather stripping firmly onto the surface of the garage door, starting from one end and working your way along the entire length. Use a roller or flat edge to ensure proper adhesion and eliminate any air bubbles or gaps.

Pay special attention to corners, joints, and areas of high wear, where additional reinforcement may be necessary. Trim any excess weather stripping as needed to achieve a clean and professional finish. Once installed, allow the adhesive to cure fully according to the manufacturer's recommendations before operating the garage door.

Selecting Weather Stripping with FIX N GO

When it comes to determining the correct weather stripping on a commercial garage door, FIX N GO Garage Door Repair employs a meticulous approach tailored to each client's specific needs. By conducting a thorough assessment of the garage door's condition, including inspecting the current weather stripping and identifying any common issues such as wear and tear or poor installation, FIX N GO ensures that the chosen weather stripping solution is precisely matched to the door type and environmental conditions. With a keen focus on selecting high-quality materials and employing proper installation techniques, FIX N GO guarantees that the weather stripping provides optimal sealing, insulation, and durability, ultimately enhancing the longevity and efficiency of the commercial garage door.

Conclusion

The importance of proper weather stripping for commercial garage doors cannot be overstated. By providing a reliable barrier against external elements such as weather, debris, and noise, well-installed weather stripping ensures not only the comfort and safety of employees but also the preservation of valuable assets within commercial spaces. Moreover, correct weather stripping contributes significantly to the longevity and efficiency of garage doors, reducing energy costs, minimizing maintenance requirements, and extending the overall lifespan of the door system. Investing in high-quality weather stripping tailored to the specific needs of your commercial garage door is not just a prudent decision but a strategic one, offering long-term benefits in terms of performance, durability, and operational excellence.